APPLICATION PROCEDURES

- Removal of the plaster and deep cleaning of the joints, with removal of the incoherent bedding mortar. Surface cleaning using a suitable method (sandblasting, pressure washing, etc.). At the end of cleaning, the load-bearing elements of the masonry must be clearly visible, free of dust, patinas, encrustations and weak or inconsistent parts on the surface, with well-deepened joints, in order to create “support steps” for the reinforced plaster and thus favoring a solid meshing and perfect collaboration with the load-bearing elements of the masonry.

- Drill the substrate according to a grid dimensioned during the design phase (usually from 2 to 4 holes/m²). Insertion in the holes of helical bars in stainless steel HELIX STEEL AISI 304, with the diameter of the bars chosen according to the structural needs. Fixing the bars with SYNTECH FIX EP chemical anchor or, alternatively, with ANCHORSANA FIX hydraulic binder-based stucco.

- Priming the substrate with BOND HG adhesive latex with pozzolanic reaction, applied with a roller, brush or spray, immediately before applying the mortar. Consumption about 200 gr/m².

- Manual or mechanical application (spray), on the edge of the masonry, of UNISAN composite mortar, fiber-reinforced with double type of READYMESH fibers (glass and polypropylene), dehumidifying, with very high breathability, class R (restoration according to UNI EN 998/1), to based on hydraulic binders with a low content of soluble salts, with mechanical resistance in class R2 (according to UNI EN 1504/3), reaction to fire class A1 (EN 13501-1), permeability to water vapor 11 μ (UNI EN 1015-19), compressive strength after 28 days > 20 MPa (UNI EN 12190), flexural strength after 28 days > 4 MPa (UNI EN 12190) modulus of elasticity 11 GPa (EN 13412), maximum granulometry of the aggregate 1,5 mm. Mix the product with water using a suitable mechanical mixer for at least two minutes and, in any case, until a homogeneous and lump-free mixture is obtained. Carry out a first layer of low thickness rough coat, making sure that the mortar penetrates inside the skinned joints and filling them (help the penetration of the mortar with a brushing operation using a hard bristle brush). Proceed with the first repair layer of the section up to approximately half of the expected total thickness. Position the ARMAGLASS STRUCTURA 330 fiberglass mesh, taking care to partially drown the mesh on the first layer of still fresh mortar. Wait for the first layer to harden, then apply the second layer of UNISAN mortar, until the required reinforcement section is completed (on average from 2 to 4 cm in total). Consumption of UNISAN mortar approx. 15 kg/m² per cm of thickness

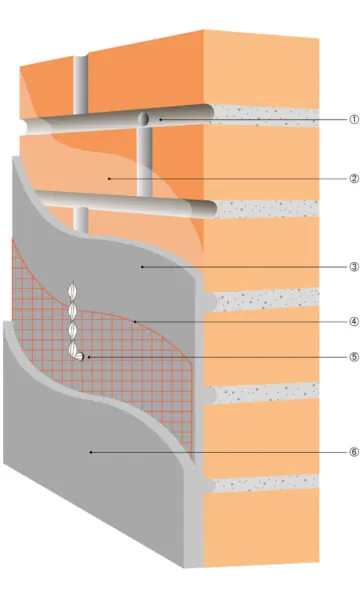

Application stratigraphy

- Cleaning of the joints and hole for housing the helical bar

- Priming the substrate with BOND HG

- UNISAN mortar (1st layer)

- ARMAGLASS STRUCTURA 330 embedded in the 1st layer of UNISAN

- Insertion of HELIX STEEL AISI 304 helical bar and fixing with SYNTECH FIX EP chemical anchor (bend the helical bar to L in order to support the ARMAGLASS STRUCTURA 330 mesh)

- UNISAN (2nd layer)

SYSTEM COMPONENTS

Bond HG

Adhesive multifunctional binding latex, in clear coloured rosy viscous solution, based on a special elastomer in aqueous dispersion, coalescence promoters, de-aerating agents and fillers with superpozzolanic reactivity. Bond HG is a reactive type multifunctional, flexibilising and waterproofing compound, for preparing adhesive grout, waterproofing coatings, and to improve mortar, plaster, grout and concrete adhesion, adherence, deformability, waterproofness and performance.

Bond HG

Adhesive multifunctional binding latex, in clear coloured rosy viscous solution, based on a special elastomer in aqueous dispersion, coalescence promoters, de-aerating agents and fillers with superpozzolanic reactivity. Bond HG is a reactive type multifunctional, flexibilising and waterproofing compound, for preparing adhesive grout, waterproofing coatings, and to improve mortar, plaster, grout and concrete adhesion, adherence, deformability, waterproofness and performance.

Unisan

A composite mortar that is fibre-reinforced, consolidating, dehumidifying, grey in colour and utilised for the structural restoration of crumbling old or monumental masonry. It contains no substances that are potentially harmful to masonry and is composed of NHL 3.5 natural hydraulic lime and hydraulic binders free from

soluble salts, along with silicas with pozzolanic activity, selected siliceous-calcareous aggregates, specific shrinkage-reducing agents and resistant alkaline READYMESH fibres that confer high flex-traction whilst increasing the performance of the mortar’s fracture energy. In conjunction with ARMAGLASS STRUCTURA fibreglass mesh, it is ideal for the structural restoration of old walls or crumbling constructions.

Unisan

A composite mortar that is fibre-reinforced, consolidating, dehumidifying, grey in colour and utilised for the structural restoration of crumbling old or monumental masonry. It contains no substances that are potentially harmful to masonry and is composed of NHL 3.5 natural hydraulic lime and hydraulic binders free from soluble salts, along with silicas with pozzolanic activity, selected siliceous-calcareous aggregates, specific shrinkage-reducing agents and resistant alkaline READYMESH fibres that confer high flex-traction whilst increasing the performance of the mortar’s fracture energy. In conjunction with ARMAGLASS STRUCTURA fibreglass mesh, it is ideal for the structural restoration of old walls or crumbling constructions.

Armaglass Structura 330

330 g/m2 structural reinforcement mesh with 50 x 50 mm square mesh, in alkali-resistant fibreglass, containing >16% zirconium dioxide, constructed with a leno weave and primed with thermosetting polymer. It is straightforward and quick to apply, simple to handle and easy to cut. It combines lightness and thinness with excellent mechanical properties in terms of warp and weft. Resistant to atmospheric agents and aggressive environments, conferring durability to the composite systems in which it is used. Suitable for any substrate and perfectly compatible with both cement- and lime-based mortars.

Armaglass Structura 330

330 g/m2 structural reinforcement mesh with 50 x 50 mm square mesh, in alkali-resistant fibreglass, containing >16% zirconium dioxide, constructed with a leno weave and primed with thermosetting polymer. It is straightforward and quick to apply, simple to handle and easy to cut. It combines lightness and thinness with excellent mechanical properties in terms of warp and weft. Resistant to atmospheric agents and aggressive environments, conferring durability to the composite systems in which it is used. Suitable for any substrate and perfectly compatible with both cement- and lime-based mortars.

Syntech E-Plus

Syntech Fix EP is a two-component adhesive with a ETAG 001 certified epoxy resin base, offering an elevated adhesive capacity and resistance to stresses from elevated loads, along with the rapid development of mechanical strength. It is suited to the anchoring and structural fastening of bars and metal elements on concrete surfaces, stone materials, brick, wood and building materials in general. Syntech Fix EP can also be utilised as a sealing agent between materials of different natures.

Syntech E-Plus

Syntech Fix EP is a two-component adhesive with a ETAG 001 certified epoxy resin base, offering an elevated adhesive capacity and resistance to stresses from elevated loads, along with the rapid development of mechanical strength. It is suited to the anchoring and structural fastening of bars and metal elements on concrete surfaces, stone materials, brick, wood and building materials in general. Syntech Fix EP can also be utilised as a sealing agent between materials of different natures.

Helix Steel AISI 304

Helical bar in AISI 304 stainless steel, cold drawn, with high mechanical performance, for the reinforced styling of joints and for connections, including through-holes, on masonry, reinforced concrete, arches and vaults. Suitable for the consolidation of structures in seismic areas; advantageous in combination with hydraulic binders (cement and hydraulic lime) and with resin matrix binders, it particularly facilitates the achievement of physical and mechanical performances in combination with Unisan mortar, with those of the REPAR, GROUT family and with the structural resins of the SYNTECH family. The optional accessory Connector Steel Aisi 304, supplied separately on request, allows the connection between the passing helical bar and the helical bar positioned deeply on the stripped joint.

Helix Steel AISI 304

Helical bar in AISI 304 stainless steel, cold drawn, with high mechanical performance, for the reinforced styling of joints and for connections, including through-holes, on masonry, reinforced concrete, arches and vaults. Suitable for the consolidation of structures in seismic areas; advantageous in combination with hydraulic binders (cement and hydraulic lime) and with resin matrix binders, it particularly facilitates the achievement of physical and mechanical performances in combination with Unisan mortar, with those of the REPAR, GROUT family and with the structural resins of the SYNTECH family. The optional accessory Connector Steel Aisi 304, supplied separately on request, allows the connection between the passing helical bar and the helical bar positioned deeply on the stripped joint.