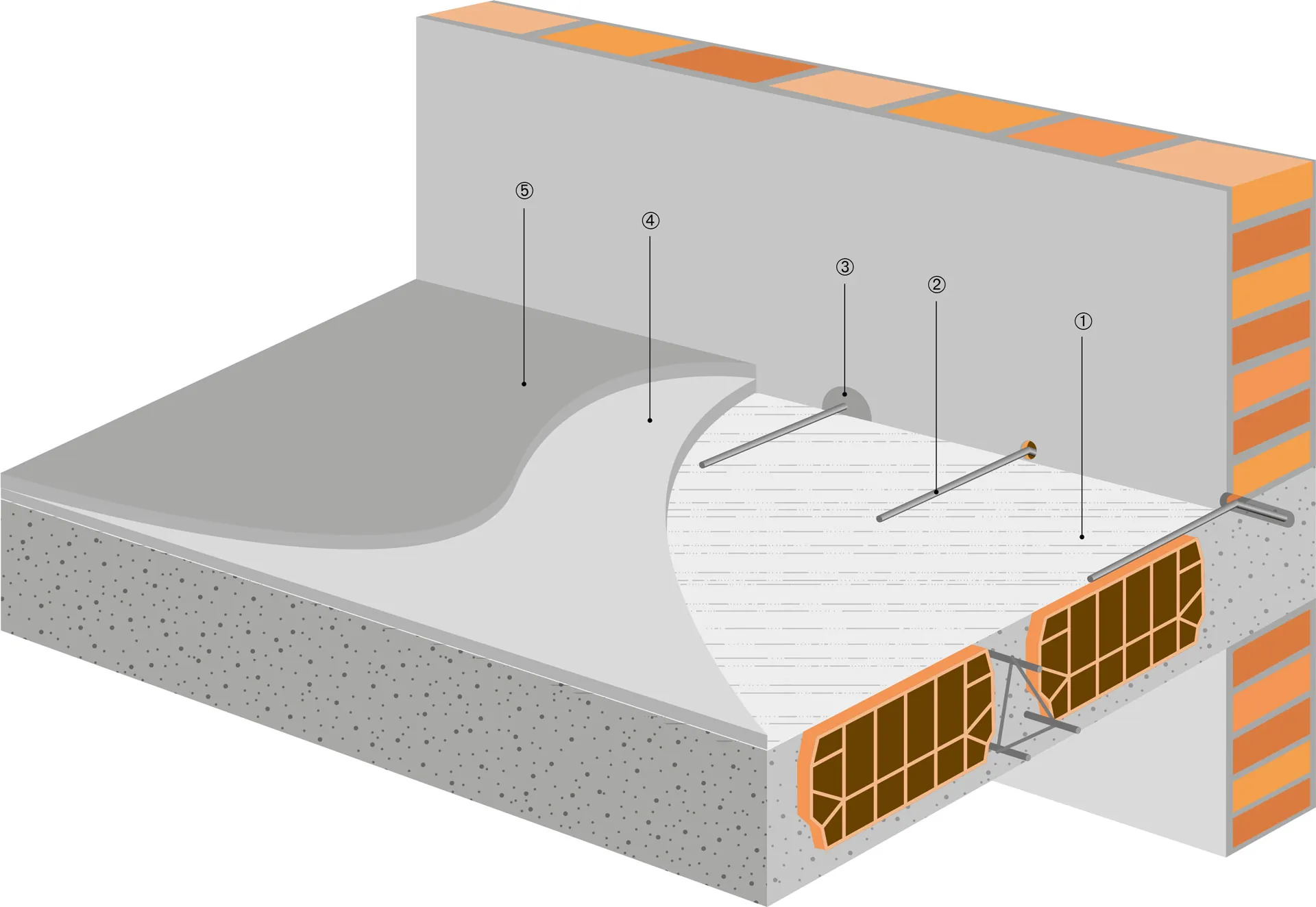

BRICK-CONCRETE FLOORS

APPLICATION PROCEDURES

- Remove the existing floors up to the load-bearing structure, removing all the inconsistent or flaking parts, until obtaining a healthy, compact and mechanically resistant support that does not lead to the detachment of subsequent applications. Scarification of the concrete layer to obtain a good degree of surface roughness (> 4 mm), necessary to ensure correct adhesion of the collaborating layer to the support, possibly assisted by metal connectors or root holes appropriately sized and distributed on the surface.

- In the perimeter walls, making holes, slightly inclined downwards, with suitably sized diameters and pitches, for the housing of metal bars with improved adhesion B 450C for the connection between walls and collaborating layer, all according to structural drawings. Cleaning of the holes and anchoring of the perimeter bars with SYNTECH PROFIX anchoring resin or with GROUT CABLE high-performance grout.

- Saturation of the substrate with water and removal of excess water on the surface.

- Mix with a vertical axis mixer, at high speed, equipped with planetary movement blades and scraper (type IMER MIX 360 or similar) according to the mixing procedure indicated in the micro-concrete data sheet.

- Casting by simple pour of HPFRC RINFOR GROUT COL micro-concrete, which combines self-leveling rheology with exceptional physical-mechanical values and which allow for structural reinforcement and an increase in the ductility of the structure. The micro-concrete must contain a very high content of steel microfibers (> 130,000 READYMESH MR-200 fibers for each 25 kg bag of premix), synthetic polyolefin fibers READYMESH PM-060 and special crystallizing additives capable of reducing free shrinkage and increasing, with self-healing, the durability of the collaborating layer. Thickness of the layer from 20 to 30 mm according to structural drawings. The consumption of the product is approx. 22.5 kg/m² per cm of applied thickness.

- On fresh micro-concrete, immediately after casting, spray or roller application of CURING AID anti-evaporant. The curing product forms a protective layer that drastically reduces the evaporation of the mixing water in the first stages of hardening of the product. Alternatively, use PE sheets

Application stratigraphy

- CONCRETE

- METAL BAR

- GROUT CABLE

- RINFOR GROUT COL

- SCREED

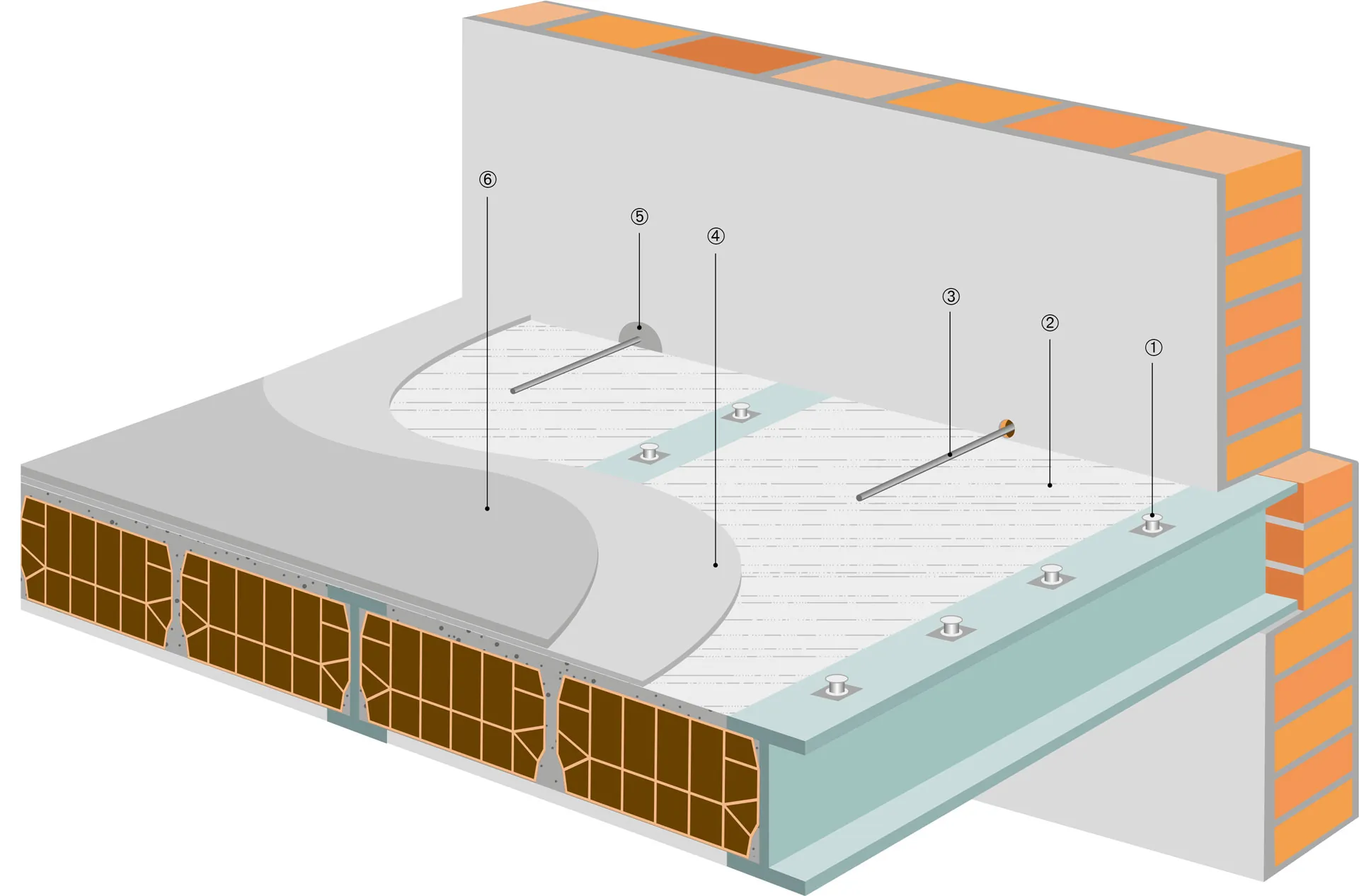

FLOORS MIXED IN STEEL AND BRICK

APPLICATION PROCEDURES

- Remove existing floors and clean all surfaces affected by the intervention, removing all inconsistent or detaching parts, until obtaining a healthy, compact and mechanically resistant support that does not lead to detachment of subsequent applications.

- Sand the extrados portion of the beams, in order to clean the metal from oxidized parts and obtain a rough surface.

- Clean the surfaces to remove dust and debris deriving from the preparatory operations.

- In the perimeter walls, making holes, slightly inclined downwards, with suitably sized diameters and pitches, for the housing of metal bars with improved adhesion B 450C for the connection between walls and collaborating layer, all according to structural drawings. Cleaning of the holes and anchoring of the perimeter bars with SYNTECH PROFIX anchoring resin or with GROUT CABLE high-performance grout.

- Make appropriate metal connections along the extrados of the beams to facilitate the structural connection of the layer of RINFOR GROUT COL; this can be achieved with connectors type TECNARIA CTF 025. The pitch of the connectors will be defined on the basis of the dimensioning of the reinforcement.

- Priming and extradoxal consolidation of brick backgrounds, using acrylic primer in aqueous dispersion, enriched with pozzolanic microsilica, BOND HG diluted 1:1 with water. This operation must be carried out 1 hour before pouring.

- Mix with a vertical axis mixer, at high speed, equipped with planetary movement blades and scraper (type IMER MIX 360 or similar) according to the mixing procedure indicated in the micro-concrete data sheet.

- Casting by simple pour of HPFRC RINFOR GROUT COL micro-concrete, which combines self-leveling rheology with exceptional physical-mechanical values and which allow for structural reinforcement and an increase in the ductility of the structure. The micro-concrete must contain a very high content of steel microfibers (> 130,000 READYMESH MR-200 fibers for each 25 kg bag of premix), synthetic polyolefin fibers READYMESH PM-060 and special crystallizing additives capable of reducing free shrinkage and increasing, with of self-healing, the durability of the collaborating layer. Thickness of the layer from 20 to 30 mm according to structural drawings. The consumption of the product is approx. 22.5 kg/m² per cm of applied thickness.

- On fresh micro-concrete, immediately after casting, spray or roller application of CURING AID anti-evaporant. The curing product forms a protective layer that drastically reduces the evaporation of the mixing water in the first stages of hardening of the product. Alternatively, use PE sheets

Application stratigraphy

- CONNECTOR

- CONCRETE LAYER

- METAL BAR

- RINFOR GROUT COL

- GROUT CABLE

- SCREED

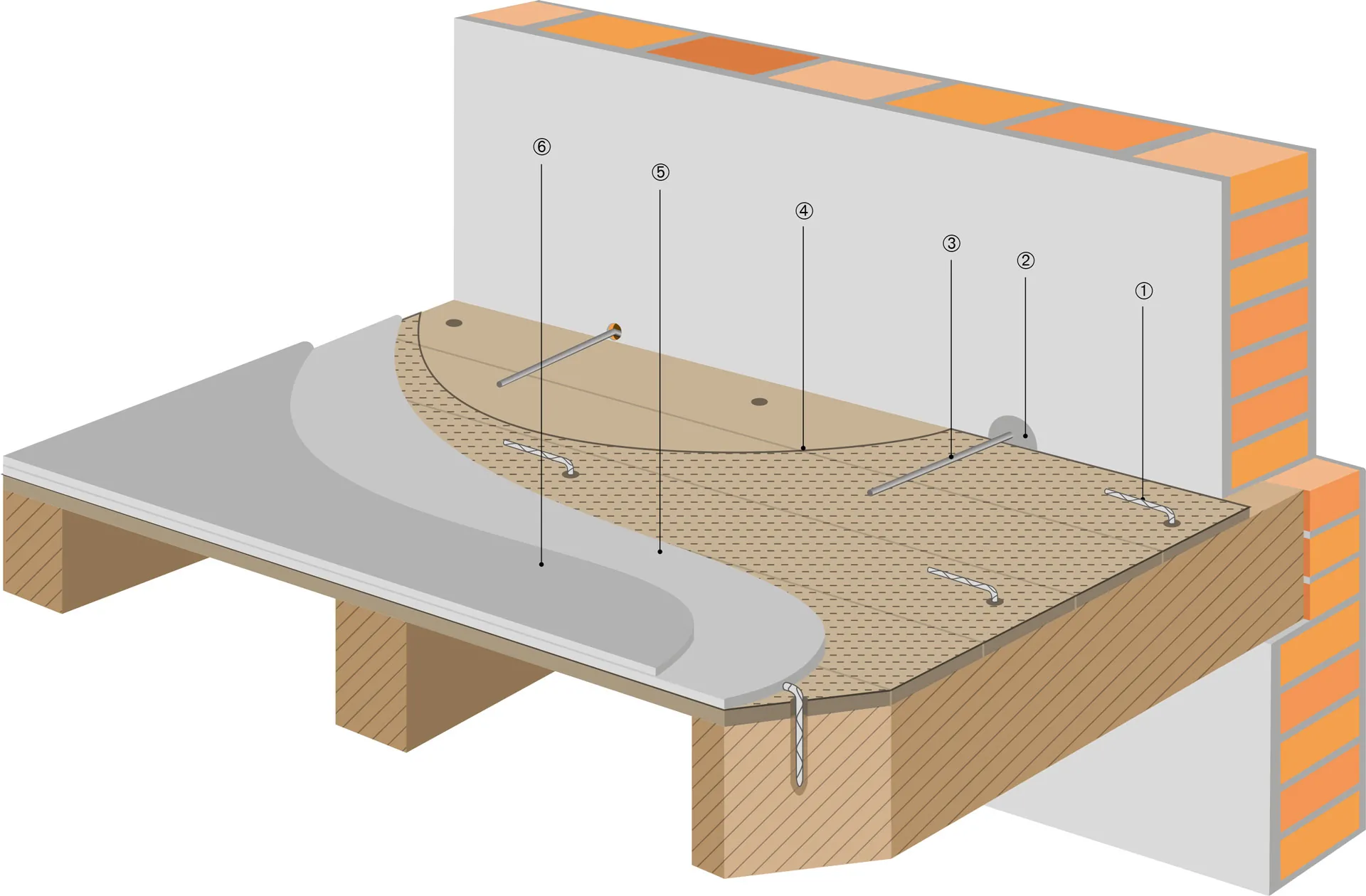

WOODEN FLOORS

APPLICATION PROCEDURES

- Remove floors and all inconsistent materials by exposing the wooden plank.

- Place a polyethylene sheet or a microporous sheet of adequate thickness on the wooden boards, the rolls of which must be applied so as to create a 10 cm overlap to be sealed using an adhesive tape. If necessary, proceed to secure the sheets with nails, in order to prevent the percolation of the mortar on the floor below.

- In the perimeter walls, making holes, slightly inclined downwards, with suitably sized diameters and pitches, for the housing of metal bars with improved adhesion B 450C for the connection between walls and collaborating layer, all according to structural drawings. Cleaning of the holes and anchoring of the perimeter bars with SYNTECH FIX EP resin for anchoring or with GROUT CABLE high-performance grout.

- Fit the HELIX STEEL AISI 304 metal connectors (Ø 10 mm) along the wooden beams. This connection is absolutely necessary in order to allow the structural connection between the existing wooden beams and the subsequent additional layer of RINFOR GROUT COL. Bend the bars at 90° in their emerging part so as to be incorporated in the pour of fiber-reinforced mortar RINFOR GROUT COL. The distance, the driving depth and the length of the section of the bar bent and incorporated in the mortar, must be defined following appropriate sizing.

- Mix with a vertical axis mixer, at high speed, equipped with planetary movement blades and scraper (type IMER MIX 360 or similar) according to the mixing procedure indicated in the micro-concrete data sheet.

- Casting by simple pour of HPFRC RINFOR GROUT COL micro-concrete, which combines self-leveling rheology with exceptional physical-mechanical values and which allow for structural reinforcement and an increase in the ductility of the structure. The micro-concrete must contain a very high content of steel microfibers (> 130,000 READYMESH MR-200 fibers for each 25 kg bag of premix), synthetic polyolefin fibers READYMESH PM-060 and special crystallizing additives capable of reducing free shrinkage and increasing, with self-healing, the durability of the collaborating layer. Thickness of the layer from 20 to 30 mm according to structural drawings. The consumption of the product is approx. 22.5 kg/m² per cm of applied thickness.

- On fresh micro-concrete, immediately after pouring, spray or roller application of CURING AID anti-evaporant. The curing product forms a protective layer that drastically reduces the evaporation of the mixing water in the first stages of hardening of the product. Alternatively, use PE sheets

Application stratigraphy

- HELIX STEEL AISI 304

- GROUT CABLE

- METAL BAR

- SEPARATOR COVER

- RINFOR GROUT COL

- SCREED

SYSTEM COMPONENTS

Syntech E-Plus

Syntech Fix EP is a two-component adhesive with a ETAG 001 certified epoxy resin base, offering an elevated adhesive capacity and resistance to stresses from elevated loads, along with the rapid development of mechanical strength. It is suited to the anchoring and structural fastening of bars and metal elements on concrete surfaces, stone materials, brick, wood and building materials in general. Syntech Fix EP can also be utilised as a sealing agent between materials of different natures.

Syntech E-Plus

Syntech Fix EP is a two-component adhesive with a ETAG 001 certified epoxy resin base, offering an elevated adhesive capacity and resistance to stresses from elevated loads, along with the rapid development of mechanical strength. It is suited to the anchoring and structural fastening of bars and metal elements on concrete surfaces, stone materials, brick, wood and building materials in general. Syntech Fix EP can also be utilised as a sealing agent between materials of different natures.

Grout Cable

Super-fluid, injectable, cementitious grout with very high flowability and stability, moderately expansive in the plastic phase, for fixings, anchors, wall consolidation, fillings, filling of post-tension sheaths, etc., based on high-strength cements, specific additives, fillers superpozzolanic reagents. Maximum particle size 0.06 mm.

Grout Cable

Super-fluid, injectable, cementitious grout with very high flowability and stability, moderately expansive in the plastic phase, for fixings, anchors, wall consolidation, fillings, filling of post-tension sheaths, etc., based on high-strength cements, specific additives, fillers superpozzolanic reagents. Maximum particle size 0.06 mm.

Helix Steel AISI 304

Helical bar in AISI 304 stainless steel, cold drawn, with high mechanical performance, for the reinforced styling of joints and for connections, including through-holes, on masonry, reinforced concrete, arches and vaults. Suitable for the consolidation of structures in seismic areas; advantageous in combination with hydraulic binders (cement and hydraulic lime) and with resin matrix binders, it particularly facilitates the achievement of physical and mechanical performances in combination with Unisan mortar, with those of the REPAR, GROUT family and with the structural resins of the SYNTECH family. The optional accessory Connector Steel Aisi 304, supplied separately on request, allows the connection between the passing helical bar and the helical bar positioned deeply on the stripped joint.

Helix Steel AISI 304

Helical bar in AISI 304 stainless steel, cold drawn, with high mechanical performance, for the reinforced styling of joints and for connections, including through-holes, on masonry, reinforced concrete, arches and vaults. Suitable for the consolidation of structures in seismic areas; advantageous in combination with hydraulic binders (cement and hydraulic lime) and with resin matrix binders, it particularly facilitates the achievement of physical and mechanical performances in combination with Unisan mortar, with those of the REPAR, GROUT family and with the structural resins of the SYNTECH family. The optional accessory Connector Steel Aisi 304, supplied separately on request, allows the connection between the passing helical bar and the helical bar positioned deeply on the stripped joint.

Curing Aid

Curing adjuvant, based on special acrylic resins in aqueous dispersion; applied by spraying, on fresh concrete surfaces. It reduces the sudden loss of the mixing water by evaporation, thus contributing to the improvement of the general characteristics of the finished product.

Unlike treatments based on wax or synthetic oils, Curing Aid is not a hydro-oleo repellent substance.

Curing Aid bases its working principle on the cross-linking of a copolymer particularly similar to the constituents of cement-based mixes. The copolymer inhibits the evaporation of water and is chemically fixed with the support.

Curing Aid, thanks to this polymerization process, is not a potentially detaching substance with respect to subsequent coating treatments, unlike the common anti-evaporating agents present on the market that base their effectiveness on active hydro-oil repellent substances.

Curing Aid

Curing adjuvant, based on special acrylic resins in aqueous dispersion; applied by spraying, on fresh concrete surfaces. It reduces the sudden loss of the mixing water by evaporation, thus contributing to the improvement of the general characteristics of the finished product. Unlike treatments based on wax or synthetic oils, Curing Aid is not a hydro-oleo repellent substance. Curing Aid bases its working principle on the cross-linking of a copolymer particularly similar to the constituents of cement-based mixes. The copolymer inhibits the evaporation of water and is chemically fixed with the support. Curing Aid, thanks to this polymerization process, is not a potentially detaching substance with respect to subsequent coating treatments, unlike the common anti-evaporating agents present on the market that base their effectiveness on active hydro-oil repellent substances.