LOW THICKNESS REINFORCEMENT WITH

FIBER-REINFORCED MICRO-CONCRETE (HPFRC)

APPLICATION PROCEDURES

- Mechanical scarification, sandblasting, hydro-scarification or other treatment of the support suitable for removing all the degraded parts of the existing concrete and obtaining a good degree of surface roughness necessary to ensure correct adhesion of the collaborating layer to the support.

- After saturating the substrate with water, preparation of perfectly sealed formworks. It is recommended to reinforce the formwork by intensifying the steel stirrups. Adopt casting stages no higher than 3 meters.

- Mix with a vertical axis mixer, at high speed, equipped with planetary movement blades and scraper (type IMER MIX 360 or similar) according to the mixing procedure indicated in the micro-concrete data sheet.

- Casting by simple pouring from above of RINFOR GROUT COL micro-concrete, which combines self-leveling rheology with exceptional physical-mechanical values and which allow for structural reinforcement and increase in the ductility of the structure. The micro-concrete must contain a very high content of steel microfibers (> 130,000 READYMESH MR-200 fibers for each 25 kg bag of premix), synthetic polyolefin fibers in READYMESH PM-060 and special crystallizing additives capable of reducing free shrinkage and increasing, with a self-healing process, the durability of the reinforcement. Thickness of the layer from 30 mm to 60 mm according to structural drawings. The consumption of the product is approx. 22.5 kg/m² per cm of applied thickness.

- Take care of the curing of the casting according to the prescriptions described in the “Guidelines for the installation of structural concrete” of the Higher Council of Public Works.

- After adequate curing of the reinforcement, smooth the surfaces with RASOCOAT high-adhesion smoothing compound, applied with two coats with a total thickness of about 2 mm

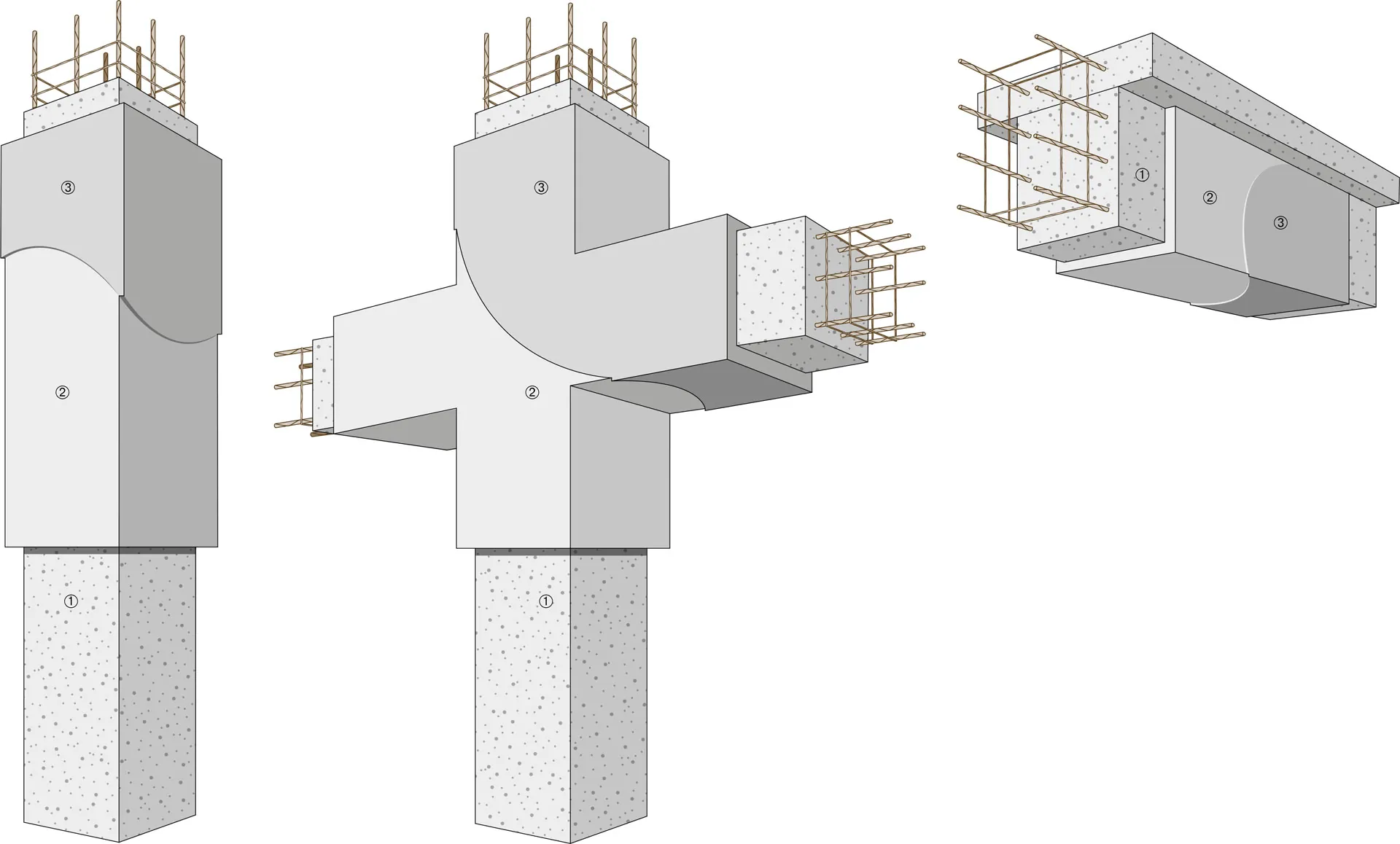

Application stratigraphy

- EXISTING CONCRETE

- RINFOR GROUT COL

- RASOCOAT

SYSTEM COMPONENTS

Rasocoat

Premixed single-component powder compound, based on hydraulic binders, water-dispersible resins, selected siliceous and calcareous aggregates, specific agents, for the preparation, with the addition of water only, of a thixotropic adhesive mortar usable for the fine civil finishing of concrete elements, cement plasters, cement-lime mortar, autoclaved aerated concrete blocks, plastic scratched concrete, tiled coverings, HPFRC conglomerates. Rasocoat, in combination with ARMAGLASS STRUCTURA fibreglass mesh, constitutes the finishing mortar of the RINFOR SYSTEM 3 anti-overturning system (consult the website www.groutpower.com).

Rasocoat

Premixed single-component powder compound, based on hydraulic binders, water-dispersible resins, selected siliceous and calcareous aggregates, specific agents, for the preparation, with the addition of water only, of a thixotropic adhesive mortar usable for the fine civil finishing of concrete elements, cement plasters, cement-lime mortar, autoclaved aerated concrete blocks, plastic scratched concrete, tiled coverings, HPFRC conglomerates. Rasocoat, in combination with ARMAGLASS STRUCTURA fibreglass mesh, constitutes the finishing mortar of the RINFOR SYSTEM 3 anti-overturning system (consult the website www.groutpower.com).